ICHIKAWA FACTORY

Introduction of Ichikawa Plant

Established: 1967 Started as a newly built, fully-automatic factory.

Number of employees: 230

Business: Manufacturing, painting, and inspection of glass containers for cosmetics

The Ichikawa Plant has a full set of facilities, including glass melting furnace, that can cover all processes from mixing glass raw materials, melting, molding, painting, inspection through to shipping in a consistent manner within the same factory.

Business introduction

-

1.Design

We create product drawings and mold drawings based on design images from customers.

-

2.Raw materials

In addition to silica sand, which is the primary raw material, the plant reuses the cullets made by crushing bottles in the plant.

-

3.Feeder

Control the temperature of raw material, melted at 1500 ℃, to 1300 to 1100℃.

-

4.Gob cut

Automatically weigh and cut the material to match the product.

-

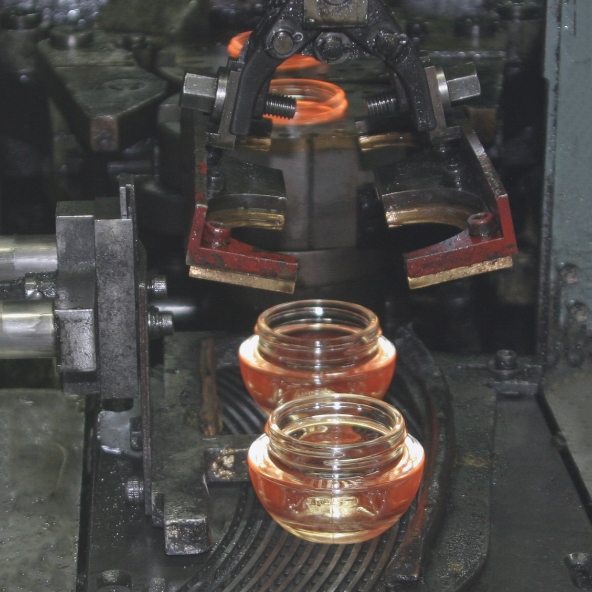

5.Bottle manufacturing

Mold the melted glass in two steps, coarse mold and finishing mold.

-

6.Fire polish

Smooth the surface with a burner.

-

7.Slow Cooling

Cool bottles slowly from around 600 to 700 ℃ to ambient temperature.

-

8.Automatic inspection

Inspect bottles with various testers and automatically identify and reject defective bottles.

-

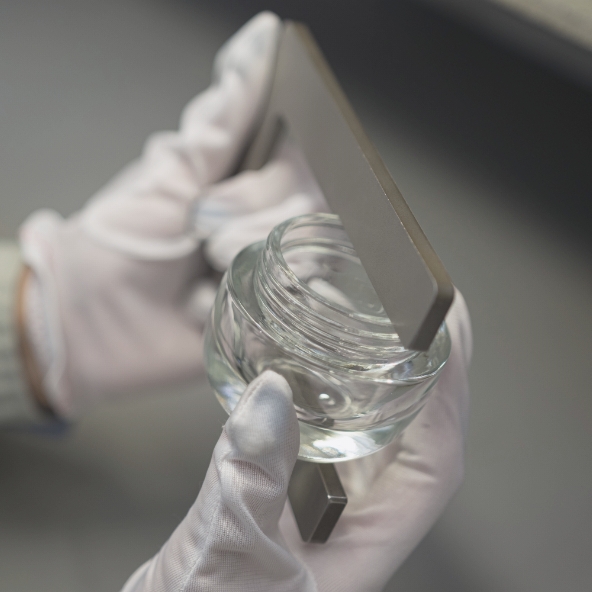

9.Gauge inspection

Inspectors individually check bottles whether bottles are made to the correct dimensions or the cap work properly.

-

10.Paint

A wide range of paintwork is applied on the surface of bottles to match the product.

-

11.Paint inspection

Visually inspect for color inconsistency.

-

12.Shipping

Products that passed the inspection are wrapped in cartons and shipped sequentially.